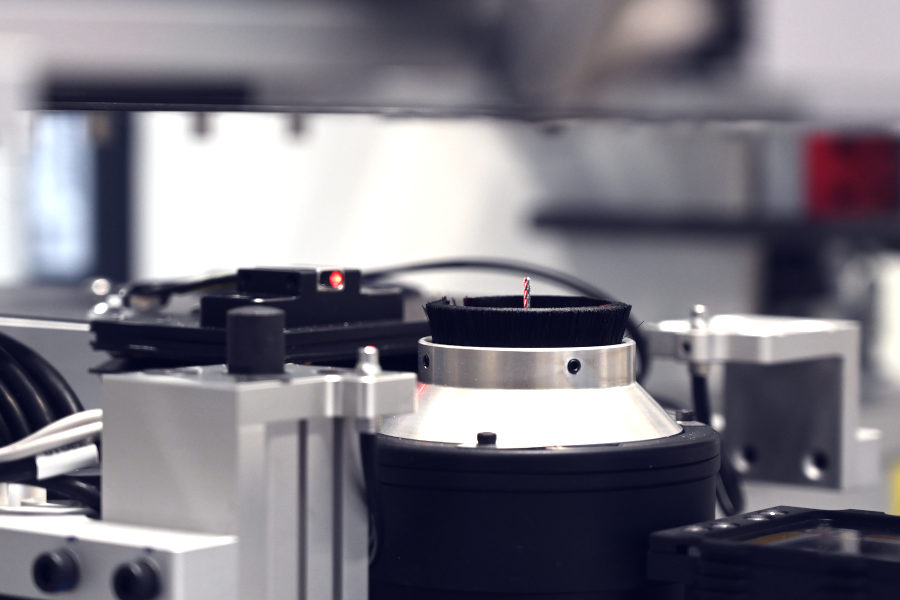

1000 BR EVO2

Fast and flexible PCB depaneling with all options available and seamlessly integrated to any output system.

Flexibility and high output can now easily be combined. The machine can be delivered with a servo gripper for full flexibility, with a dedicated multi-gripper for higher output, or with a combination of both. Adding the popular underboard support function turns the machine into a true high-volume machine – which can be converted back to flexible high-mix machine in a matter of minutes.

Optical routing verification, improved dust extraction, additional cleaning functions and other highly appreciated options gives you the best process performance available on the market.

The output of ready products is easily configured to your needs due to the unique frame design. Singulated PCBs can be placed on trays up to 400x600mm, on a flatbelt, on a shuttle, directly to box-build housing, or any other output solutions that fits your production flow the best.

Equipped with extensive software options covering off-line CAD import, MES connectivity and traceability, Cencorp 1000 BR EVO2 meets the toughest quality demands in electronics industry today.

Key technical information

Basic info

Min. panel size: 75x75mm (LxW)

Max. panel size: 400x350mm (LxW)

Top clearance: 100mm

Bottom clearance: 40mm

Software options

Offline programming

MES integration

Automatic Cpk-monitoring

Automatic program changeover

Machine options

Milling quality inspection

Automatic bit verification

Additional cleaning units

Dual lane conveyor

Output options:

Flatbelt

Tray

Shuttle

Tailor-made solutions

Contact Info

Whether you’re looking to boost your production capacity with a new machine or need support with your existing equipment – we are always ready help