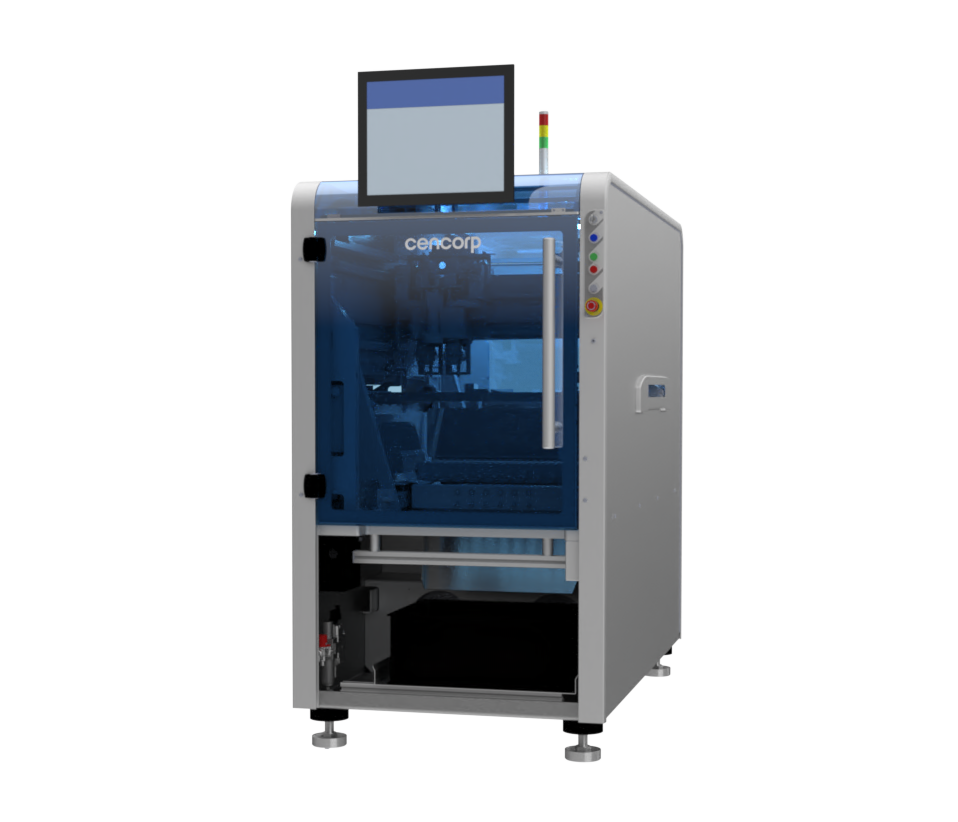

Raptor

When you need speed, our Raptor is the machine for you. With a maximum placement capacity of up to 5100 cph this machine sets a new standard in the through hole placement market. Equipped with a fast dual head pick and place robot this machine will be an ideal work horse for the mass production lines.

The machine can hold up to 6 feeders of all standard and custom feeder types offered by Cencorp except tube feeders. Panels are supported from underneath to ensure a high-quality process. Radial components can be pre-formed in the feeders to hold them in position in the panel without clinching.

When volume is in focus

Producers of consumer electronics struggle finding reliable automation solutions for high volume placement of through-hole components. The Raptor combines the well-known process control features from larger Cencorp cells with an extremely fast pick&place gantry and all the component preforming features needed in the feeders to make the process run smoothly.

Designed for large batch production in high volumes, the Raptor will serve the needs of even the most demanding customers.

Key technical information

Basic info

Min panel size: 50 x 50 mm

Max panel size: 310 x 300 mm

Top clearance: 40 mm

Bottom clearance: 35 mm

Maximum component height: 30 mm

Cycle time: 0,7 – 1,2 s

Basic function

Automatic gripper finger change

Manually changeable product support plates

Optional function

Radial feeder component lead forming, which ensures that components

Stay stable in the PCB before the next process phase.

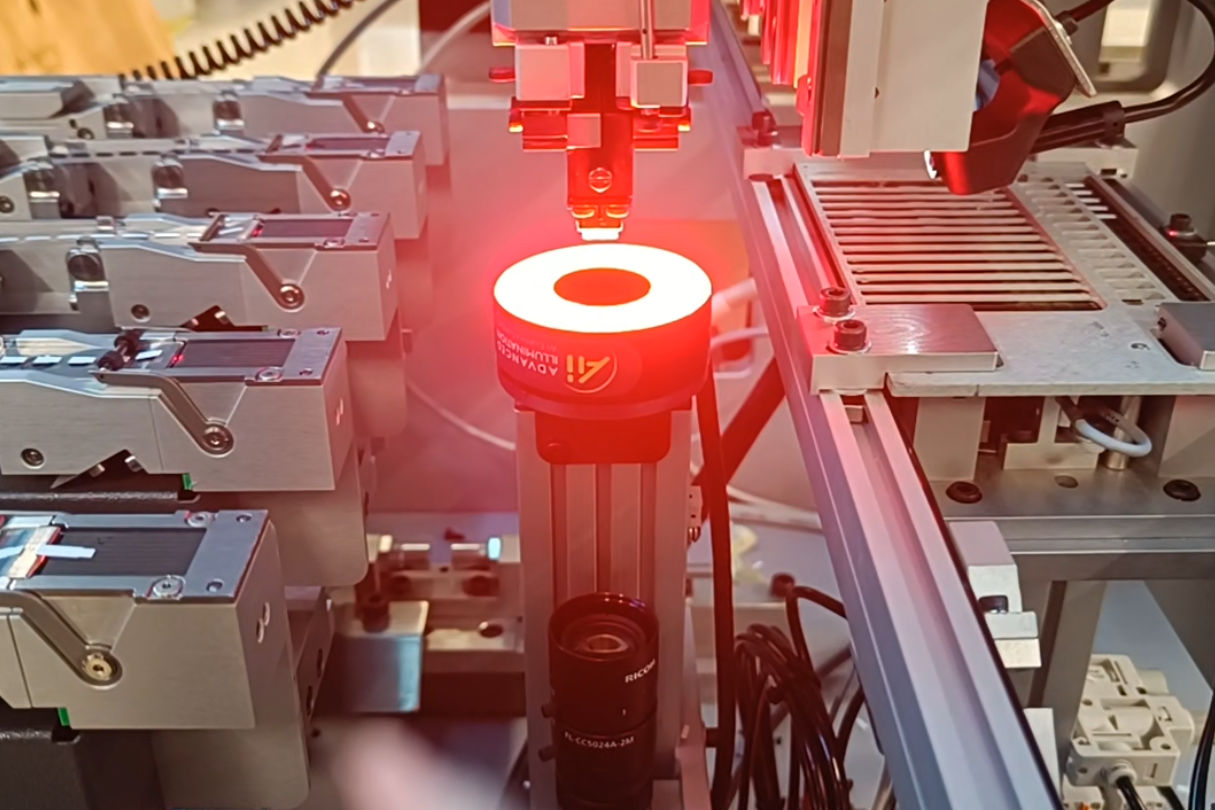

Vision system

Correction of PCB position

Correction of component placement position

Contact Info

Whether you’re looking to boost your production capacity with a new machine or need support with your existing equipment – we are always ready help