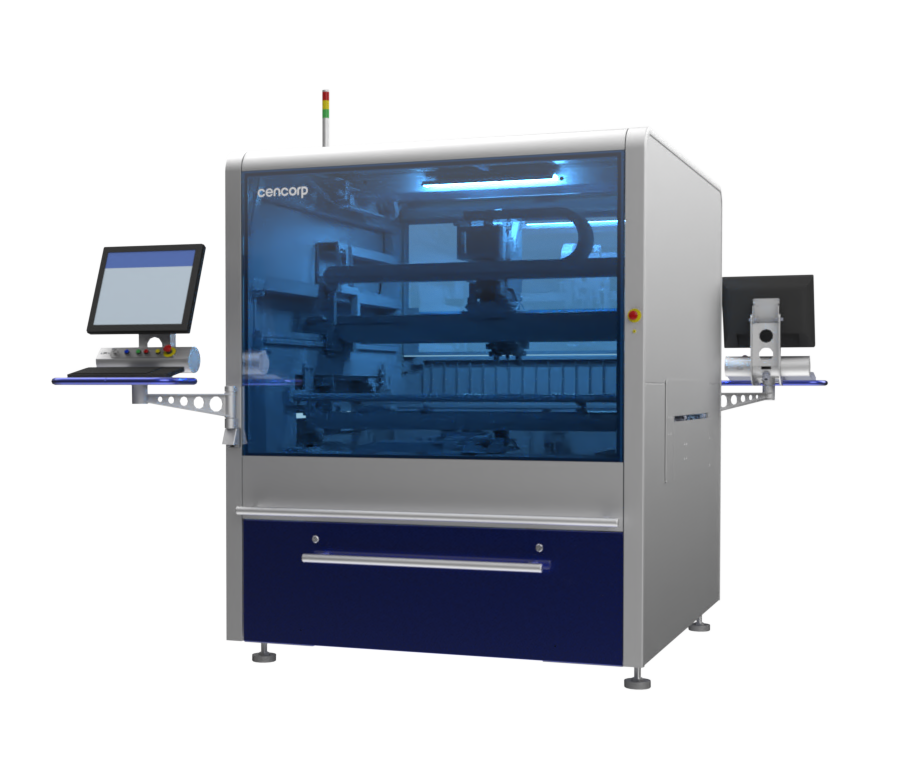

1500 OF

The 1500 OF is the most flexible odd-form placement machine on the market. With the large feeder bench, it can handle up to 24 different components in all sizes. The machine is very popular among manufacturers of inverters, onboard chargers, motor controllers and similar products with a high number of through-hole components to place. The robust gantry enables also semi-press fit capability with assembly forces up to 600N with full force monitoring during the placement process.

Batch size one production

Utilizing the CiS program suite, we can offer our odd form customers state of the art in through-hole placement technology. Batch size one production lines where every PCB going through the line can be unique. No product specific programming when component coordinates and clinching directions are downloaded directly from the customers’ BOM files. Hundreds of products variants produced seamlessly in the same line without product change over. Prototypes of new product variants can be tested without programming and without stopping normal production.

Key technical information

Basic info

Panel sizes: min 55 x 55 mm, max 580 x 450 mm

Top clearance: 60 mm

Bottom clearance: 40 mm

Maximum component dimensions: 100 x 50 mm, 200 g

Cycle time: 1,8 – 2,5s

Basic function

Component soft grip and presence detection

Programmable pusher force

Fully programmable clinching with component leg detection

Optional function

Automatic program change

Semi-press fit, up to 600N placement forces

CiS SW suite

Vision system

Q-vision

Q-scan

Q-check

Contact Info

Whether you’re looking to boost your production capacity with a new machine or need support with your existing equipment – we are always ready help